Dr. Taewon Kim’s team of photovoltaic energy convergence research group of Korean Institute of Industrial Technology (KITECH, President Yong-Soo Lee) developed an original technology to refine organic light-emitting materials in bulk for fine OLED TV at low price.

Dr. Kim’s team established a new concept for the refining technology by using Ionic Liquids (ILs), and it can solve issues of high cost·low yield rate arisen in production of the organic light-emitting material for the OLED TV.

Ionic Liquids are liquids that only consist of positive and negative ions at room temperature and stays in liquid form at high vacuum (~100℃) with almost no volatility. Recently, ILs became a future clean solvent in green chemistry field with a strength of good solubility for high molecular substance and a feature of metal salts.

Until now, ‘sublimation refining method’ has been used to get high purify organic light-emitting material by utilizing the difference of sublimation points between vaporization and solidification of a material. However, cons of this method are low yield rate and very high production cost because it is impossible to realize complete auto and continuous process.

To address this issue, Dr. Kim’s team started developing the large scale refining technology for the organic light-emitting materials at low cost since 2011 and applied for original patent in December, 2012. Their effort on verifying the possibility of the technology’s application produced this result in 19 months.

The key of the result is the application of the high purity refining technology on the organic light-emitting material for the OLED TV by focusing on the non-volatile feature of ILs at high vacuum·high temperature.

This technology uses a principle of separating impurities in the order of vaporizing the organic light-emitting material in a vacuum chamber; dissolving it in a liquid filter of ionic liquid; and recrystallizing supersaturated material in the liquid. It enables to get 99.95% of high purity organic light-emitting material through one refining process.

It is a completely new concept of large scale refining method based on the non-volatility characteristic of ionic liquid at high vacuum·high temperature.

The team is credited with the success of new technology development which can overcome the cons of the existing sublimation refining method including refinery yield rate, automation and continuous process of equipment, and efficiency of mass production. It is also expected to bring a huge cost reduction effect by recycling; collect and reprocess during refinery process, of the expensive but non-volatile ionic liquid.

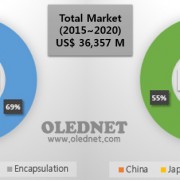

According to “2014 OLED Emitting Material Annual Report Market Forecast (~2020)” by a professional OLED market research firm, UBI Research, the OLED emitting material market is expected to grow to 1.3 trillion won in 2017 from 2014 estimation of 543 billion won. Forecasted annual growth rate is over 30% and experts see that the growth will be much larger if large size display market including the AMOLED TV expends in full-scale.

Dr. Taewon Kim, said, “this technology increased the yield rate and decreased the production cost by more than 50%. And an ultimate goal is to reduce the current price by one tenth” and “technology development is in progress with companies.” He also said, “the success is a game changer with enormous potential to turn the OLED TV market-to-explosively grow” and “based on the low-cost and large scale refining original technology, domestic businesses will largely contribute to preoccupy the global market of forward-backward industry regarding the OLED TV.”

The team currently applied 16 cases for patent with related process․equipment technology in and out of the country and plans active technology transfer to related businesses.

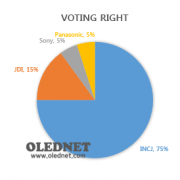

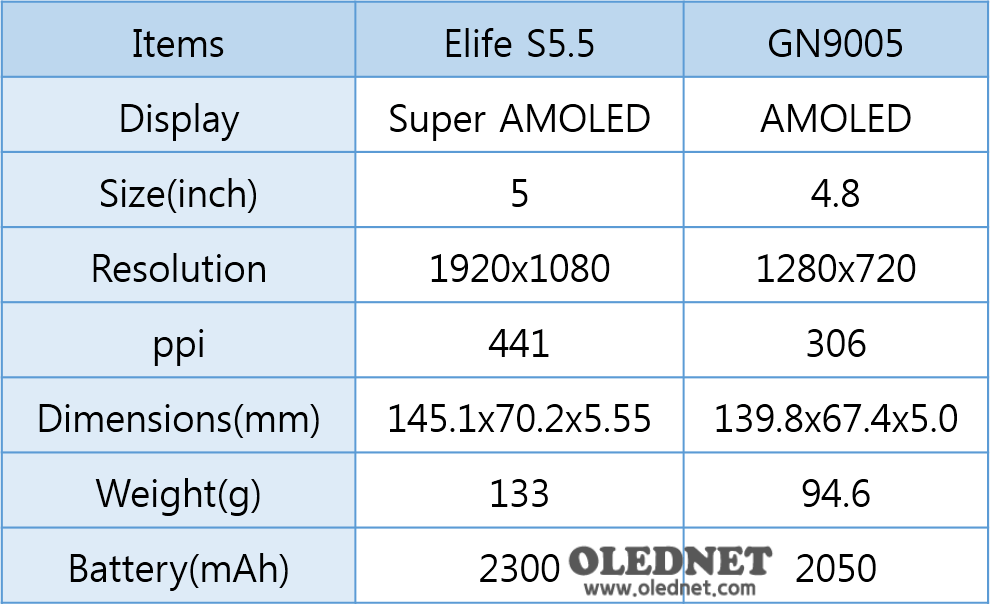

<Comparison of refining methods for organic light emitting materials Source: KITECH>