In SID 2015 Display Week (31 May – 5 June), LG Display’s CTO In Byeong Kang gave a keynote speech. He explained that future display in everyday lives will be actively applied to home, office, street, and mobile device areas through various applications including window, ceiling, mirror, kitchen, automotive, desk, commercial, and wearables. He added that OLED will be the answer to key technology of flexible display (curved, rolling, and folding), large-area transparent, and excellent image quality.

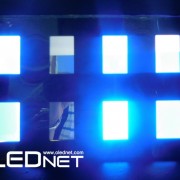

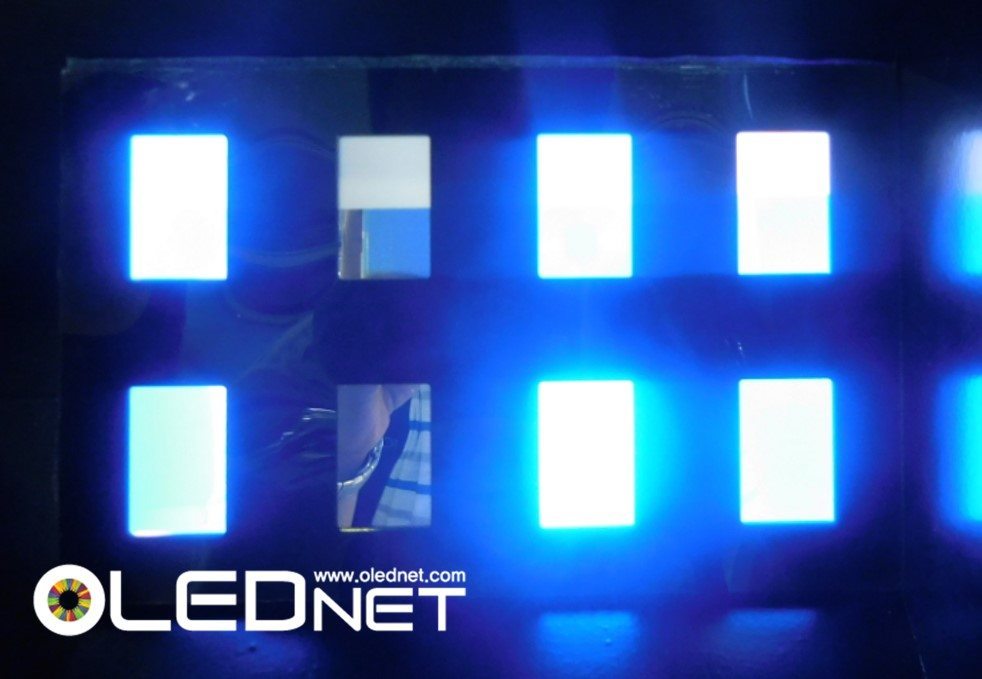

Key issues of flexible are bending radius and reliability. Kang emphasized that in order to reduce the bending radius, thinner substrate is needed, and to improve reliability, new material, components development, and internal and external shock mechanism research is important. He mentioned that although OLED is good for transparent’s transparency, light control, and reflectivity as key technology, LCD and LED display also have advantages of their own in transparent display realization. Kang concluded the presentation with the emphasis on the need of expansion into automotive, watch, architecture, and furniture companies from existing panel, material, and components companies’ ecosystem for commercialization of flexible and transparent display.

LG Display is currently mass producing plastic OLED panel for smart watch, and aiming for 80% automotive display market occupation in 2018 with approx. US$ 2,000,000,000,000 of revenue. In SID 2015, LG Display exhibited 18 inch rollable OLED panel, and 12.3 inch automotive OLED panel. Through the OLED and ecosystem’s expansion, it is anticipated LG Display will lead flexible and transparent display market following OLED TV.