[SID 2015] AUO’s New RGBY Pixel Structure, Can It Be an Answer for Low-Powered OLED?

Display consumes most power out of smartphone battery usage. This means that low-powered display is most important in lengthening the smartphone’s usage time.

AMOLED panel is a self-illuminating device driven by each RGB subpixels, and theoretically power consumption should be much lower than LCD’s which requires BLU (back light unit) to be constantly lit. However, as OLED materials’ performance, particularly blue, is not sufficient the power consumption falls short of expectation.

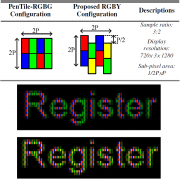

In SID 2015, AUO gave a speech on new RGBY pixel structure attempting to solve the power consumption issue. AUO applied PSA (power saving algorithm) and SPR (sub pixel rendering) of RGBY method, not RGBG structure’s pentile method of existing FMM RGB mechanism, and reported that this showed higher definition and lower power consumption compared to the pentile method RGB applied for high resolution. Particularly it was shown that it can be a key technology for low-powered AMOLED panel through HD 4.65inch (317ppi) panel demo; the power consumption of yellow sub pixel (efficiency 80-120 cd/A) was reduced by 16-20% in comparison to existing RGB method.

Dr. Meng-Ting Lee of AUO told the audience yellow sub pixel application improves high resolution, high definition, low power consumption, and panel’s lifetime simultaneously and that AUO’s RGBY SPR and PSA technology can become key technology for AMOLED panel for mobile device.