[IFA 2015] Directions for LG Electronics’ OLED TV?

During the media day event for IFA 2015 (September 4 – 9), LG Electronics introduced diverse products centering around OLED TV such as LCD TV, G4, and G Watch Urbane.

LG Electronics clearly confirmed that the ultimate TV for the company is OLED TV. At the company booth under the title of the Evolution of TV, LG Electronics revealed that the TV’s final destination is OLED TV.

At this exhibition, the OLED TV presentation theme returned to the flat design from HDT’s emphasis on black and previous curved design. Until now, curved design focused OLED TV were exhibited, but with the spotlight on flat design in IFA 2015, LG Electronics strongly hinted that future LG OLED TV will switch to flat products.

Competitors greatly improved contrast ratio through application of LCD TV and HDR. LCD’s basic contrast ratio is approximately 1,000:1, and in premium products currently being mass produced it has improved to 3,000:1. However, as OLED TV does not use backlight, the minimum contrast ratio is 100,000:1 with maximum of infinite contrast ratio. Through IFA 2015 LG Electronics is planning to actively release HDR technology applied products. In order to achieve this, the company will demonstrate HDR transmission with broadcasting companies such as BBC and publicize OLED TV’s black and white’s superiority over LCD TV.

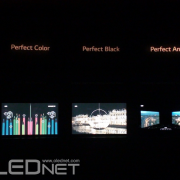

LG Electronics provided ‘perfect color’, ‘perfect black’, and ‘perfect angle’ as the superior characteristics of OLED TV. These advantages are inherent characteristics that LG’s WRGB OLED TV can provide that show excellence over LCD TV in any environment.

However, the OLED TV presented in this exhibition did not show much improvement from one in IFA 2014, leading to disappointment. It is a point of concern whether WRGB OLED TV has already reached its limitation.

![[Fig. 1], Source: UDC, IMID 2015](http://www.olednet.com/wp-content/uploads/2015/08/야31.jpg)

![[Fig. 2], Source: UDC, IMID 2015](http://www.olednet.com/wp-content/uploads/2015/08/야4.jpg)

![[Fig. 3], Source: UDC, IMID 2015](http://www.olednet.com/wp-content/uploads/2015/08/야51.png)